Hob Coating

Hob Coating

A hard coating with a thickness of 2-3um increase the life of the hobs, or permits higher cutting rates, for the coating of the gear hobs, the PVD(Phisical Vapor Deposition) method is used. It is a plasma vacuum thin layer method, during which high-purity materials are transferred into a plasma via an arc cathode sputtering. By reacting with reactive gases such as oxygen, nitrogen or carbon, ceramic hard material layers are deposited on the tools.

The generated hard material PVD layers normally consist of refractory metals such as chrome, titanium or tantalum, alloyed with aluminum, silicone and a non-metal(oxygen, nitrogen, boron and carbon). Layer systems which are used for gear cutting today are titanium-aluminum-nitrogen(TiAiN) or aluminum-chrome-nitrogen(AiCrN). The high-performance coatings used are made up of several layers which enables both a high elasticity and high wear resistance.

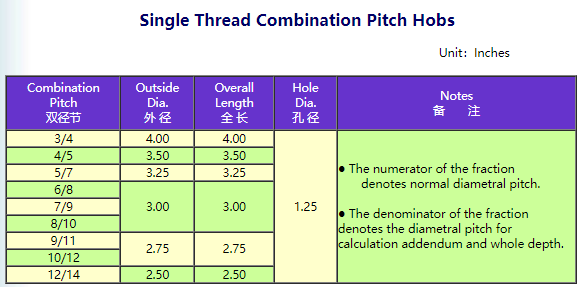

- Single Thread Combination Pitch Gear Hobs

- PA20° Module m2.5 Standard Involute Gear Hob

- Plunge Cut Shaving Cutter

- PA20° Standard Involute Gear Milling Cutter with Module m0.9

- PA20° PCD 100mm Bowl Type Gear Shaper Cutter with Module m1~m6

- PA20° Standard Gear Milling Cutter with Module m16

- Hob specification criteria